|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

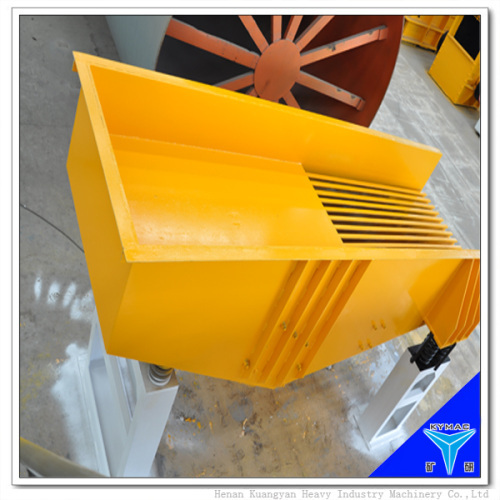

Vibrating feeder for building

| Price: | 6000.0~7500.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Easy maintenance.less investment, an energy efficient

2.Extra heavy-duty construction

3.Exclusive vibrator technology

4. Less power consumption

Application of Vibratory Feeder :

Vibrating Feeder is a kind of linear direction feeding equipment. It features smooth vibrating, reliable operation, long service life and being suitable for feeding. They are widely used in mining, building-material, silicate and chemical industry in the crushing and screening plants. In the Sand-Stone production line, it can send materials to crusher evenly and continuously and at the same time, it can screen materials roughly. It can be used in these areas such as metallurgical industry, coal mining industry, mining-selecting, building, chemical and grinding industry, etc.

Vibrating Feeder Features and Benefits:

Vibrating feeder is generally installed in front of the primary crusher, which conveys big blocks continuously and evenly while removing the dirt and impurities by screen bars. It can effectively control the feeding capacity to match with the capacity of the whole crushing plant. It has features of strong construction, antistrike and wearable.

1, Vibrating feeder features smooth vibrating, Double deck, reliable operation, a long span life and suitability for feeding .

2, Flexible design and easy adjustment

3, Easy maintenance.less investment, an energy efficient

4, Extra heavy-duty construction

5, Exclusive vibrator technology

6, Less power consumption, small start-up current, low noise.

7, reliable operation, long service life,

8, low noise, low power consumption,

9, easy to adjust, simple structure, easy to install,

10, light weight, small volume, simple maintenance.

Vibrating Feeder Working Principle:

Vibrating feeder consists of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gearsare jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the two eccentric shafts start rotating to producea linear huge power which forces the feeder to vibrate. Through the vibration,the materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller parts will fall down, and avoiding the furthercrushing, so screening purpose can be reached.

Specifications of vibrating Feeder:

| Type | Max feed size(mm) | Capacity(t/h) | Power(kw) | Weight | Size of runnel(mm) | Overal dimensions |

| (t) | (L*W*H)(mm) | |||||

| GZD-850×3000 | 400 | 80~120 | 1.5×2 | 3.9 | 850×3000 | 3110×1800×1600 |

| GZD-960×3600 | 500 | 120~210 | 2.2×2 | 4 | 960×3600 | 3850×1950×1630 |

| GZD-1100×3800 | 540 | 160~340 | 3.7×2 | 4.1 | 1100×3800 | 4150×2000×1650 |

| GZD-1200×4900 | 580 | 280~500 | 5.5×2 | 4.5 | 4900×1200 | 5200×2050×1700 |

| GZD-1300×4900 | 650 | 450~600 | 7.5×2 | 5.2 | 4900×1300 | 5200×2350×1750 |

About our company

We, Henan Kuangyan Heavy Industry Machinery Co., Ltd., are professional manufacturer which specialized in heavy equipment development and production. Our main product include mining equipment, ore dressing equipment and building material making equipment, such as various crusher, ball mill, magnetic separators, bricks and blocks machines, cement and lime production line, AAC block production line, ceramic sand production line, etc. Our factory locates in the middle of China, Henan Province. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Certificates

Workshop

Delivery

International Corperation

Our service

1>.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

2>.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3>.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

4>.We provide one-year warranty to make sure your machine runs consistently.