|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

symons cone crusher parts cone crusher bearing small cone crusher

| Price: | 25000.0~999999.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Cone crusher:

1.Sturdy durable

2.Automatic control system

3.Thin oil lubrication

4.Hydraulic system

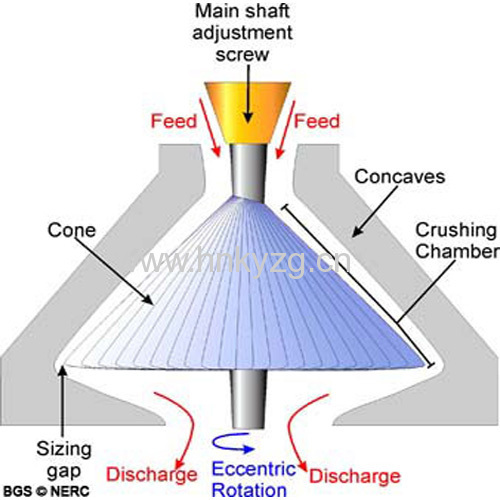

Working principle of Ore Cone Crusher:

Ore Cone Crusher materials by the working surface between the movable cone and fixed cone. The movable cone of the cone crusher is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve. And the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are driven by the eccentric shaft sleeve together. The eccentric shaft sleeve is driven by horizontal shaft and fimbriated gear. And the wheel of the conveyor belt is driven by motor through-V-belts.

The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve of cone crusher rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, rocks are grinded into pieces, when the cone leaves, grinded materials is discharged from the discharge hole. The fixed cone can be ascended or descended by adjusting setting to adjust the width of discharge hole, consequently the output size is determined.

Application of cone crusher

Cone crusher is a kind of crushing machine commonly used in mining, metallurgical industry, construction, road construction and chemical industry. Our cone crusher can be used to crush hard and medium hard minerals, rocks, iron ores, limestone, copper ores, quartz, granite, sandstones, etc. In a whole production line, usually, the cone crusher is used for secondary or tertiary crushing process, or first crushing.

Structure characteristic of cone crusher

A). Simplicity of design and rugged construction have made cone crusher ideal for crushing operations.

B). The spring-loaded release system allows any uncrushable material to pass through without causing any damage.

C). The lubrication unit is interlock with the main motor for additional safety as a standard equipment.

D). A rid liner is provided inside the bottom section of the frame to help protect it from wear.

E). The cone crusher is designed for secondary or tertiary crushing purpose both in stationary and portable application and portable applications for highly abrasive materials.

Main technical parameters

Model | Cone diameter (mm) | Max feeding size (mm) | Discharging hole size (mm) | Capacity | Motor Power (kw) | Main shaft swaying frequency (r/min) | Weight (t) | Dimension (L×W×H) (mm) |

PYB | 600 | 65 | 12-25 | 20-40 | 30 | 356 | 5 | 2234×1370×1675 |

PYD | 600 | 35 | 3-13 | 12-23 | 30 | 356 | 5.5 | 2234×1370×1675 |

PYB | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692×1640×2350 |

PYZ | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 11.2 | 2692×1640×2350 |

PYD | 900 | 50 | 3-13 | 15-50 | 55 | 333 | 11.3 | 2692×1640×2350 |

PYB | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790×1878×2844 |

PYZ | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 25 | 2790×1878×2844 |

PYD | 1200 | 50 | 3-18 | 18-105 | 110 | 300 | 25.3 | 2790×1878×2844 |

PYB | 1750 | 215 | 25-50 | 280-480 | 155 | 245 | 50.3 | 3910×2894×3809 |

PYZ | 1750 | 185 | 10-30 | 115-320 | 155 | 245 | 50.3 | 3910×2894×3809 |

PYD | 1750 | 85 | 5-15 | 75-230 | 155 | 245 | 50.2 | 3910×2894×3809 |

PYB | 2200 | 300 | 30-60 | 590-1000 | 280-260 | 220 | 80 | 4622×3302×4470 |

PYZ | 2200 | 230 | 10-30 | 200-580 | 280-260 | 220 | 80 | 4622×3302×4470 |

PYD | 2200 | 100 | 5-10 | 120-342 | 280-260 | 200 | 81.4 | 4622×3302×4470 |

Company profile

Henan Kuangyan Heavy Machinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations