|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

Small jaw crusher made in Henan

| Price: | 1000.0~2000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.high broken ratio

2.homogenous final product size

3.simple structure Mn13 plate

4.High quality and reasonable price

5. Reliable supplier

Product Description

Information of mining jaw crusher

It features in high broken ratio, even product size, simple construction, reliable operation, easy maintenance, and low consumption. It mainly applicable to various ores and big blocks' primary and secondary crushing, widely used in mining ,quarry, metallurgy, building material, highway, railway, construction waste processing, water conservancy and chemical industry, etc.

Jaw crusher machine is mainly used for primarily crushing the raw materials, so that is also called primary jaw crusher or primary crushers.

Jaw crusher is one of the most important crushing machines in the stone crushing production line. It can be not only used for crushing stone materials, pebble and coal and be called stone jaw crusher, but used for manufacturing cement aggregate.

This crushing plant has many features such as deep crushing chamber, both big and small feeding mouth, controllable feeding granularity and the production capacity is high. Henan Kuangyan Heavy Industry Machinery Co., Ltd is the largest jaw crusher supplier in China and produces jaw crushing plant with various models. The main models are mini jaw crusher, PE jaw crusher. Welcome to our company for visit and purchase.

This series of Jaw Crushers are designed by our engineers with large reduction ratio, even granularity, simple structure, reliable operation, convenient maintenance, low cost, Jaw Crusher is widely used in mining, metallurgy, construction, highway, railroad, and chemistry industries. This jaw crusher uses motor as its power, through the motor's wheels; the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track.

The main technical parameters of mining jaw crusher

MODEL | Feed openingsize (mm) | Max feed size (mm) | DISCHARGE SIZE (mm) | Capacity (t/h) | Rotary speed | Power (kw) | Weight (t) | Overall dimension (mm) |

PE-150X250 | 150X250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720X660X850 |

PE-200X300 | 200X300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910X750X990 |

PE-200X350 | 200X350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000X870X990 |

PE-250X400 | 250X400 | 210 | 20-60 | 5-20 | 300 | 18.5 | 2.8 | 1300X1090X1270 |

PE-400X600 | 400X600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730X1730X1630 |

PE-500X750 | 500X750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980X2080X1870 |

PE-600X750 | 600X750 | 500 | 150-200 | 80-240 | 275 | 55 | 15.8 | 2070X2000X1920 |

PE-600X900 | 600X900 | 500 | 65-160 | 50-180 | 250 | 75 | 17 | 2190X2206X2300 |

PE-750X1060 | 750X1060 | 630 | 80-140 | 110-320 | 250 | 90 | 29 | 2660X2430X2800 |

PE-800X1060 | 800X1060 | 640 | 160-220 | 130-330 | 250 | 110 | 29.8 | 2710X2430X2800 |

PE-830X1060 | 830X1060 | 650 | 110-320 | 150-336 | 250 | 110 | 30.7 | 2740X2430X2800 |

PE-870X1060 | 870X1060 | 660 | 200-260 | 190-336 | 250 | 110 | 31.5 | 2810X2430X2800 |

PE-900X1060 | 900X1060 | 685 | 230-290 | 230-390 | 250 | 110 | 33 | 2870X2420X2940 |

PE-900X1200 | 900X1060 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380X2870X3330 |

PE-1000X1200 | 900X1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480X2876X3330 |

PE-1200X1500 | 1000X1200 | 1020 | 150-300 | 400-800 | 180 | 160 | 100.9 | 4200X3300X3500 |

PEX-150X750 | 1200X1500 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200X1530X1060 |

PEX-250X750 | 150X750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380X1750X1540 |

PEX-250X1000 | 250X1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560X1950X1390 |

PEX-250X1200 | 250X1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140X1660X1500 |

PEX-300X1300 | 300X1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720X1950X1600 |

Note: The above technical parameters are just for your reference. If there are any changes, all parameter and overall dimension are subject to the operating instructions. If you have Any problems, please feel free to contact us. We will give you the best service and technology supporting

You may have interest in our other products as follows:

Jaw Crusher, Impact Crusher, Cone Crusher, Hammer Crusher, Compound Crusher, Box Hammer Crusher, Feeder, Ball Mill, Rod Mill, Raymond Mill, Conveyor, Vibrating Screen, Flotation Machine, Magnetic Separator, Shaking Table, Spiral Classifier, Thickener, Filter, Drier, Rotary Kiln, Sand Washer, Sand Production Line, Gold Processing Equipment, Metal Processing Equipment, etc.

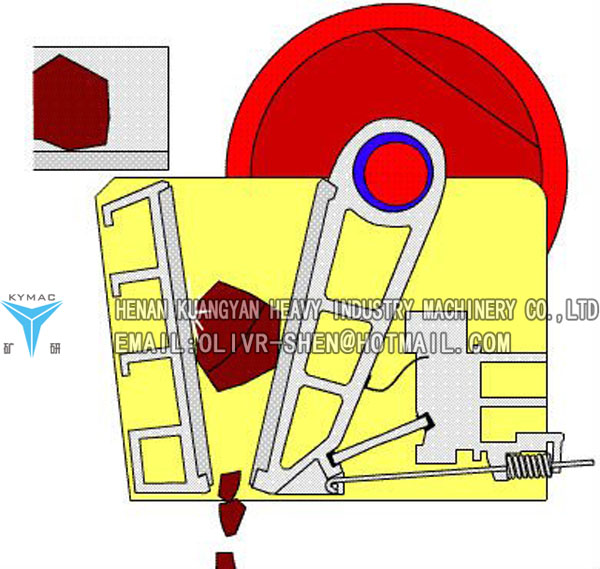

Working Principle of mining jaw crusher

Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The spaces at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

About our company

We, Henan Kuangyan Heavy Industry Machinery Co., Ltd., are professional manufacturer which specialized in heavy equipment development and production. Our main product include mining equipment, ore dressing equipment and building material making equipment, such as various crusher, ball mill, magnetic separators, bricks and blocks machines, cement and lime production line, AAC block production line, ceramic sand production line, etc. Our factory locates in the middle ofChina, Henan Province. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Certificates and honours

Workshop

Delivery

International Cooperation

Our servive

1>.Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

2>.Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3>.After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

4>.We provide one-year warranty to make sure your machine runs consistently.

We always offering lifelong services and provide spare parts for a long term.

WELCOME TO VISIT OUR FACTORY!