|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

High efficient ore stone crusher

| Price: | 80000.0~100000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

1.the separation of ferrous mineral

2.The separation of nonferrous and mineral

3.The recovering of gravity separation medium

4..ISO,CQC,BV

Black stone crusher machine in Henan

Jaw crusher machine is mainly used for primarily crushing the raw materials, so that is also called primary jaw crusher or primary crushers.

Jaw crusher is one of the most important crushing machines in the stone crushing production line. It can be not only used for crushing stone materials, pebble and coal and be called stone jaw crusher, but used for manufacturing cement aggregate.

This crushing plant has many features such as deep crushing chamber, both big and small feeding mouth, controllable feeding granularity and the production capacity is high. Henan Kuangyan Heavy Industry Machinery Co., Ltd is the largest jaw crusher supplier inChinaand produces jaw crushing plant with various models. The main models are mini jaw crusher, PE jaw crusher. Welcome to our company for visit and purchase.

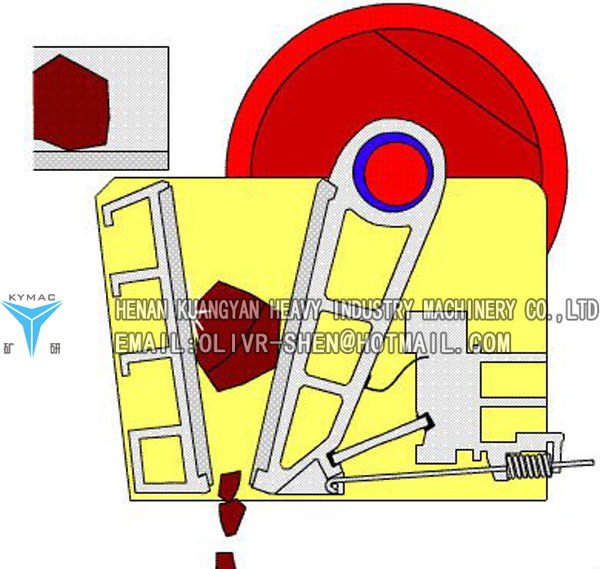

This series of Jaw Crushers are designed by our engineers with large reduction ratio, even granularity, simple structure, reliable operation, convenient maintenance, low cost, Jaw Crusher is widely used in mining, metallurgy, construction, highway, railroad, and chemistry industries. This jaw crusher uses motor as its power, through the motor's wheels; the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track.

Jaw stone crusher plant is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The spaces at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

Jaw Crusher Plant Working Principle:

Jaw Crusher Plant Features:

1. Jaw stone crusher plant is stable performance;

2. Jaw stone crusher plant is even final particles and high crushing ratio;

3. Optimum structure for reliable quality;

4. Easy access to wear areas for inspection and maintenance;

5. Product size adjustable during operation;

6. Efficient, non-choking operation;

7. Higher crushing ratio; Lower power consumption;

8. Excellent jaw plate material.

Jaw Crusher Main technical parameters

MODEL | Feed openingsize (mm) | Max feed size (mm) | DISCHARGE SIZE (mm) | Capacity (t/h) | Rotary speed | Power (kw) | Weight (t) | Overall dimension (mm) |

PE-150X250 | 150X250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720X660X850 |

PE-200X300 | 200X300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910X750X990 |

PE-200X350 | 200X350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000X870X990 |

PE-250X400 | 250X400 | 210 | 20-60 | 5-20 | 300 | 18.5 | 2.8 | 1300X1090X1270 |

PE-400X600 | 400X600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730X1730X1630 |

PE-500X750 | 500X750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980X2080X1870 |

PE-600X750 | 600X750 | 500 | 150-200 | 80-240 | 275 | 55 | 15.8 | 2070X2000X1920 |

PE-600X900 | 600X900 | 500 | 65-160 | 50-180 | 250 | 75 | 17 | 2190X2206X2300 |

PE-750X1060 | 750X1060 | 630 | 80-140 | 110-320 | 250 | 90 | 29 | 2660X2430X2800 |

PE-800X1060 | 800X1060 | 640 | 160-220 | 130-330 | 250 | 110 | 29.8 | 2710X2430X2800 |

PE-830X1060 | 830X1060 | 650 | 110-320 | 150-336 | 250 | 110 | 30.7 | 2740X2430X2800 |

PE-870X1060 | 870X1060 | 660 | 200-260 | 190-336 | 250 | 110 | 31.5 | 2810X2430X2800 |

PE-900X1060 | 900X1060 | 685 | 230-290 | 230-390 | 250 | 110 | 33 | 2870X2420X2940 |

PE-900X1200 | 900X1060 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380X2870X3330 |

PE-1000X1200 | 900X1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480X2876X3330 |

PE-1200X1500 | 1000X1200 | 1020 | 150-300 | 400-800 | 180 | 160 | 100.9 | 4200X3300X3500 |

PEX-150X750 | 1200X1500 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200X1530X1060 |

PEX-250X750 | 150X750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380X1750X1540 |

PEX-250X1000 | 250X1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560X1950X1390 |

PEX-250X1200 | 250X1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140X1660X1500 |

PEX-300X1300 | 300X1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720X1950X1600 |

General of applications

Magnetic Beneficiation Plant :

1.the separation of ferrous mineral

2.The separation of nonferrous and mineral

3.The recovering of gravity separation medium

4.Removing iron impurities from non-metallic mineral

5.The recovery of steel slag from the metallurgy smelting and removing from sewage

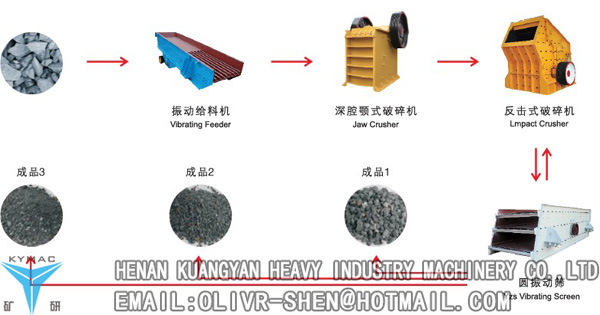

Complete Stone Production Line

Company Description

Henan Kuangyan Heavy Industry Machinery Co., Ltd. is a joint-stock enterprise which produces large-sized and medium-sized crushers and mills, mining equipments, and light AAC brick/block making machines.

Under such circumstances, we make full use of the good opportunity and try our best to have a great progress in technical transformation, innovation, improving the quality of products, and continuously expanding the domestic and overseas markets. Through years of development, our products have gained a favorable comment from markets all over the world. As the leading company in crushing & milling fields, we have developed series of newly-designed crushers by absorbing advanced scientific technology & processing experience from abroad and our experts' continuous research. It has been proved that our crushing products have covered a good market share both in domestic and overseas for high quality & easy maintenance.

Delivery

Welcome to visit our factory!