|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

Stone impact crusher mining impact crusher impact crusher

| Price: | 24500.0~25500.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.High reduction ratio

2.No-board connection

3.Final cubical shape

4.Power saving

5. ISO9001-2008,CQC,CE,BV.

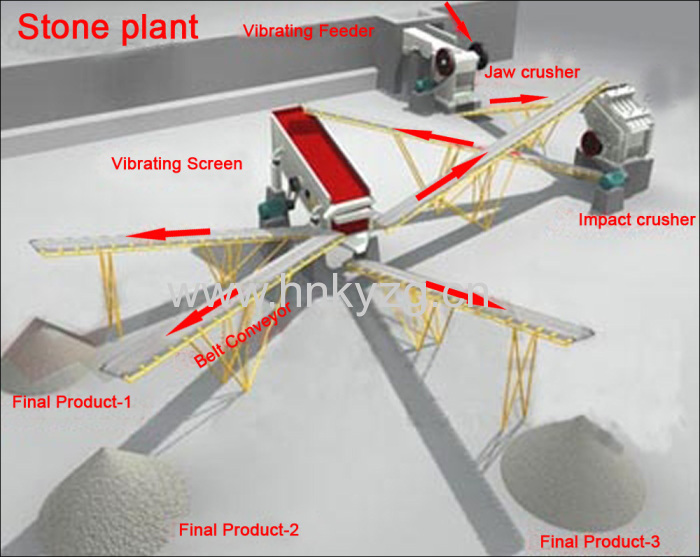

Mining Stone Crushing Machines and Impact Crusher optimized after adopting advanced techniques. It can crush granite, basalt, bluestone, etc the diameters of which are from 100mm to 500mm, and its crushing compression strength is not more than 350Mp The final product is desirable device for aggregation used in highway and railway surface and water and electricity industry.

Mining Stone Crushing Machines and Impact Crusher is the machine which breaks materials using the impact energy. The rotor rotates of our mobile crusher with a high speed driven by power motor when the machine is working. When the materials get into hammer effect area, they are impacting to break with the hammer on the rotor and then threw to the impacting position to take another crushing. After that they spring back to hammer impacting area from impact wrist plate to take crushing again. This procedure repeats itself.

Structure features of Mining Stone Crushing Machines and Impact Crusher

1.Big output opening,high crushing cavity,suitble in high hardness,big pieses and less power ;

2.The gap in the impact and the hammer plate can be adjusted,efficient control the output feed fineness, the final production has good shape;

3.Tight strucure, good equipment rigidity,big rotational inertia;

4.High hammer plate,big impact resistance and wear resistance.;

Performance characteristics of Mining Stone Crushing Machines and Impact Crusher

1, Heavy rotor design, more durable rotor, more powerful on crushing.

2, The whole bearing cast steel structure, with frame with more perfect. Enhance radial intensity housings.

3, unique plate hammer fixtures, the maintenance and remove is more convenient.

4, optimizing adjustment device back plate, adjust the more convenient.

5, bearing, strong, durable, repair the machine rate low.

6, in the hydraulic chamber structure, convenient maintenance.

7, in a new way, effectively increase the incoming material size, increase crushing ratio.

8, adjustment protection device, greatly increases the safety equipment.

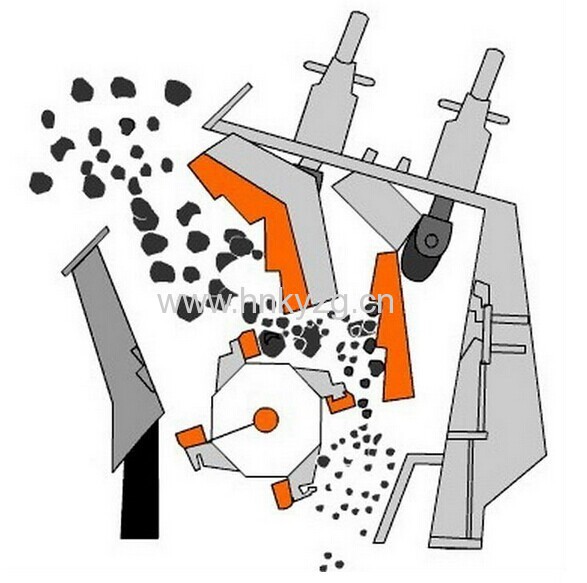

Working Principle of Impact Crusher:

When the Impact Crusher works, the motor drives the rotor rotate of the Impact Crusher with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers affect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the hammers effects for being re-crushed. The materials from large to small all to be crushed at the impact chamber repeatedly. The process won't stop till the material are crushed to the required size and then discharged from outlet of the Impact Crusher.

Main technical parameters of Mining Stone Crushing Machines and Impact Crusher

Type | Spe. (mm) | Feed opening size (mm) | Max feed size (mm) | Capacity (t/h) | Power (kw) | Overall dimension (mm) | Weight (t) |

PF-0607 | 644×740 | 320×770 | 100 | 10-20 | 30 | 2010×1490×2600 | 6.5 |

PF-0807

| 850×700 | 400×730 | 300 | 15-30 | 30-45 | 2210×1490×2670 | 8.1 |

PF-1008 | 1000×800 | 400×830 | 300 | 30-50 | 37-55 | 2400×1558×2660 | 9.5 |

PF-1010 | 1000×1050 | 400×1080 | 350 | 50-80 | 55-75 | 2400×2250×2620 | 12.2 |

PF-1210 | 1250×1050 | 400×1080 | 350 | 70-120 | 110-132 | 2690×2338×2890 | 14.9 |

PF-1212 | 1250×1250 | 400×1300 | 350 | 100-150 | 132-160 | 2690×2508×2890 | 16.3 |

PF-1214 | 1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 2690×2688×2890 | 18.6 |

PF-1310 | 1300×1050 | 490×1170 | 400 | 80-140 | 110-160 | 2780×2478×2855 | 21.2 |

PF-1315 | 1320×1500 | 860×1520 | 500 | 160-250 | 180-260 | 3096×3273×2667 | 24.3 |

PF-1520 | 1520×2000 | 830×2050 | 700 | 300-550 | 315-440 | 3581×3560×3265 | 36.5 |

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations.

Company Profile

Henan Kuangyan Heavry Machiery Co., Ltd. is specialized in heavry equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.