|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

mineral materials impact crusher hard stone impact crusher granite impact crusher

| Price: | 24500.0~25500.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.High reduction ratio

2.No-board connection

3.Final cubical shape

4.Power saving

5. ISO9001-2008,CQC,CE,BV.

Information of high quality crushing mineral materials impact crusher

Impact crusher is a kind of crushing machine, which is applicable for kinds of large, medium and small sized ores, rocks (granite, lime stone and concrete). The crusher can handle materials of the side length below 120-500mm and compression strength of the materials is less than 350Mpa. The crushing strength of our impact crusher is big.The discharge particle size is relatively small and well-distributed.And it has low power consumption. The machine can operate smoothly with low noise.

Application of high quality crushing mineral materials impact crusher

Our impact crusher is applied for crushing limestone, concrete, basalt, and especially used for the product of road stone. It is widely used in various fields of mining, smelting, building materials, highway, railway, water conservancy and chemical industry, etc.

Features of high quality crushing mineral materials impact crusher

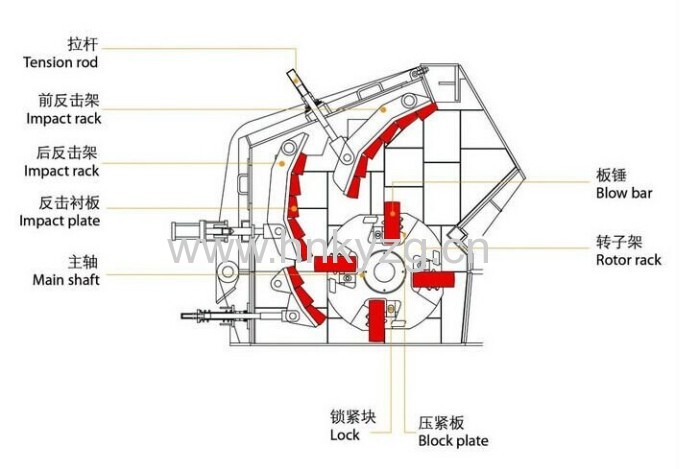

1.This crusher has reasonable structure. It is equipped with high-chromium plate hammer and unique impact plate.

2. It can crush hard rocks and has the advantages of high efficiency, energy conservation, high reduction ratio, selective crushing and so on.

3. The various adjustment range of discharge opening is to meet the different needs of users.

4. The crushing strength of our impact crusher is big.The discharge particle size is relatively small and well-distributed.And it has low power consumption.

5. Low noise and little pollution to the environment

Working principle of high quality crushing mineral materials impact crusher

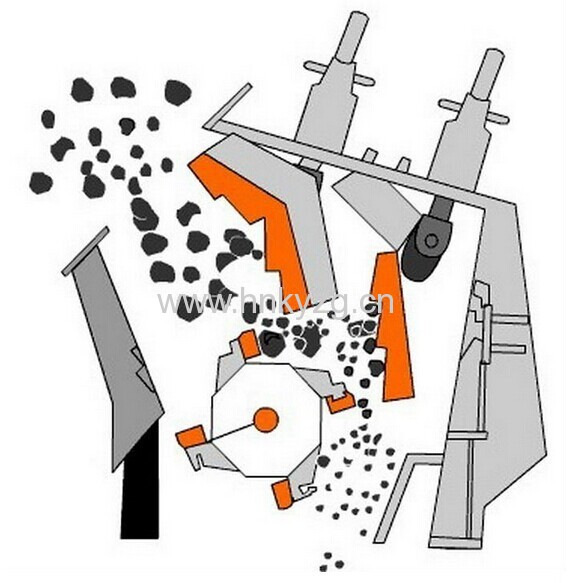

This impact crusher machine crushes materials with impact force. When the materials enter the blow bar area, they are crushed due to the high-speed impact of the blow bar and are thrown to the impact plates on the rotor for secondary crush. Then the materials will be shot back to the blow bar again for the third crush. This process repeats until the materials are crushed to the required size and discharged from the lower part of the machine. The size and shape of the finished powder can be changed by adjusting the gap between the impact rack and rotor support. The machine employs self-weigh security device in its back frame. When other objects enter the impact cavity, they will be forced out of the machine by the impact rack in the front and back of the machine.

Main technical parameters of high quality crushing mineral materials impact crusher

Type | Spe. (mm) | Feed opening size (mm) | Max feed size (mm) | Capacity (t/h) | Power (kw) | Overall dimension (mm) | Weight (t) |

PF-0607 | 644×740 | 320×770 | 100 | 10-20 | 30 | 2010×1490×2600 | 6.5 |

PF-0807

| 850×700 | 400×730 | 300 | 15-30 | 30-45 | 2210×1490×2670 | 8.1 |

PF-1008 | 1000×800 | 400×830 | 300 | 30-50 | 37-55 | 2400×1558×2660 | 9.5 |

PF-1010 | 1000×1050 | 400×1080 | 350 | 50-80 | 55-75 | 2400×2250×2620 | 12.2 |

PF-1210 | 1250×1050 | 400×1080 | 350 | 70-120 | 110-132 | 2690×2338×2890 | 14.9 |

PF-1212 | 1250×1250 | 400×1300 | 350 | 100-150 | 132-160 | 2690×2508×2890 | 16.3 |

PF-1214 | 1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 2690×2688×2890 | 18.6 |

PF-1310 | 1300×1050 | 490×1170 | 400 | 80-140 | 110-160 | 2780×2478×2855 | 21.2 |

PF-1315 | 1320×1500 | 860×1520 | 500 | 160-250 | 180-260 | 3096×3273×2667 | 24.3 |

PF-1520 | 1520×2000 | 830×2050 | 700 | 300-550 | 315-440 | 3581×3560×3265 | 36.5 |

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations.

Company profile

Henan Kuangyan Heavy Machinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.