|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

mineral flotation machine air flotation machine xjk flotation machine

| Price: | 900.0~80000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High grade oxide sulfide copper ore mines flotator machine Peru

1.capacity:100-300t/h

2.Low cost

3.Best After service

4 ISO9001 BV CE CQC

Working principle of flotation machine:

♦When the flotation equipment works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced.

♦ On one hand, ample air is absorbed and mixed with mineral slurry. On the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning.

♦ The mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed.

♦ Adjusting the height of flashboard to control liquid surface, then these foams are discharged by the scrapper plate.

Gold ore flotation machine is used for separating ferrous and non-ferrous metals. It also can be used for separation of non-metal materials such as coal fluorite and steatite. The gold ore flotation machine impeller rotates by triangle belt of the motor, with produces centrifugal function and causes negative pressure.0n one hand it draws in enough air mixed with ore magma; on the other hand it agitates to mix ore magma with chemical medicines. At the same time, Gold separator minifies bubbles so that minerals can stick above them .float on the surface of magma, and form mineralized bubbles. The height of plate can be adjusted to control fluid level so that the available bubbles can be scrapped out by scrapers.

Application of Gold Ore Flotation machine:

Gold ore flotation machine is applicable for the separation of nonferrous metal and ferrous metals, such as fluorite and talc. The gold separator impeller is driven by V-belts, which can bring the centrifugal effect to form negative pressure. While extracting sufficient air to mix with ore pulp, the gold ore flotation machine stirs ore pulp and mixes it with chemicals to form mineralized froth. By adjusting the height of the flash board to control the liquid level, the useful froth can be scraped from the loam board. The height of the strobe must be adjusted carefully to keep the stabilization of liquid level and scrape the mineralized froth to the launder. The impellers and stators of gold ore flotation machine should be kept at a distance and should be changed when worn. The bearing in the pump should be maintained every three months.

Features of flotation machine

Gold ore flotation machine has the advantages of large air-absorption capacity and low energy consumption. Every flotation machine owns three functions: air absorption, slurry absorption, and flotation separation, and the cells form a floatation separation loop by itself without any auxiliary equipment, and is allocated horizontally, which favors the change of flow. The circulation of mineral slurry is reasonable, and can avoid the disposition of coarse sand to the largest extent. There is self-control device on the surface of mineral slurry, so it is easy to adjust gold ore flotation mahine. The gold ore flotation machine impeller has backward-inclined upper and lower vanes, which produce upper and lower circulation of mineral slurry respectively.

Masin technical parameters

Model | Effective volume(m3) | Processing ability (m3/min) | Motor power(kw) | Spindle speed(r/min) | Scraper speed(r/min) | Scraper Power(kw) | Trough Size(mm) | Single Slot weight(kg) |

SF0.37 | 0.37 | 0.2-0.4 | 1.5 | 352 | 25 | 1.1 | 700*700*750 | 468 |

SF0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 900*820*950 | 600 |

SF1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1100*1100*1100 | 1873 |

SF2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1750*1600*1150 | 2538 |

SF4 | 4 | 2.0-4.0 | 15 | 220 | 25 | 1.5 | 1850*2050*1200 | 2838 |

SF8 | 8 | 4.0-8.0 | 30 | 191 | 25 | 1.5 | 2200*2900*1400 | 4129 |

SF10 | 10 | 5.0-10 | 30 | 191 | 25 | 1.5 | 2200*2900*1700 | 4486 |

SF20 | 20 | 5.0-20 | 30*2 | 191 | 25 | 1.5*2 | 2850*3800*2000 | 9828 |

Type | Effective volume(m³) | Diameter of impellor(mm) | Capacity(m³/min) | Speed of impellor(r/min) | Motor of impellor | Weight (t/single trough) |

XJK-0.35 | 0.35 | 300 | 0.18-0.4 | 470 | Y90L-4-1.5 | 0.43 |

XJK-0.62 | 0.62 | 350 | 0.3-0.9 | 400 | Y100L-4-3 | 0.86 |

XJK-1.1 | 1.1 | 500 | 0.6-1.6 | 330 | Y100M-4-5.5 | 1.38 |

XJK-2.8 | 2.8 | 600 | 1.5-3.5 | 280 | Y100M-4-11 | 2.33 |

XJK-5.8 | 1.1 | 750 | 3-7 | 240 | Y100M-4-22 | 3.533 |

About Us:

Henan Kuangyan Heavy Machienry Co., Ltd. is a joint-stock enterprise, manufacturing large-size and medium-size mining equipment which has been exported to various countries and owns high reputation. Our products mainly include:

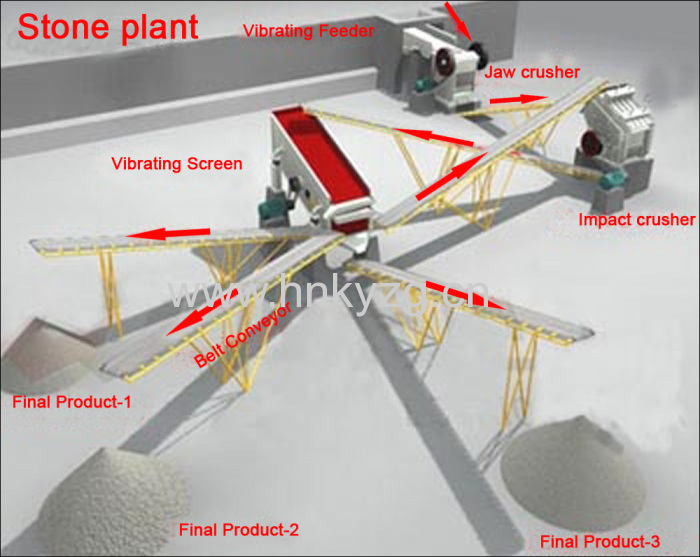

Crushing equipment: jaw crusher, impact crusher,cone crusher, hammer crusher, sand making machine, vibrating feeder, vibrating screen;

Mine-dressing equipment: ball mill, spiral chute, classifier, flotation machine, magnetic separator;

Building material equipment: rotary dryer, rotary kiln, autoclave aerated concrete equipment (AAC plant)

Production line: sand production line, stone production line, active lime production line, cement production line, AAC block plant

we specialize in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations