|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

rotary kiln active lime rotary kiln activated carbon rotary kiln

| Price: | 60000.0~900000.0 USD |

| Payment Terms: | T/T,T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rotary kiln:

1,Advanced national technologies

2,Efficiency running rate

3,High product

4)ISO CE CV CQC

Cement Rotary Kiln:

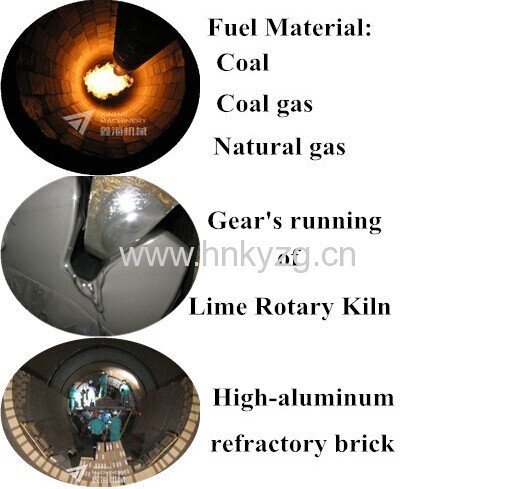

A Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process.Its fuel for this may be gas, oil or pulverized coal.The basic components of a rotary kiln are the shell, the refractory lining, support tyres and rollers, drive gear and internal heat exchangers.

Structure of Cement Rotary Kiln:

Cement rotary kiln is composed of cylinder, fireproof brick, support roller, rim, large gear ring, Small gear ring drived by motor, head kiln hood, steel sheel, cold kiln hood, fuel and gas jet.

Basic Functions of Wet Process Cement Rotary Kiln with High Temp kiln:

1)spray coal powder into kiln at a certain speed in a dispersed state; mix coal with wild;

2)strength air movement and spread speed to disperse volatile gas membrane around coal powder aggregate, expanding the touch between solid carton and second wind;

3) Add moderate fresh air to resolve hypoxic problem in the flame kernel;

4)Low The first wind volume to improve use ratio of clinker heat-recovery;

5)Suitable quickly to material change, flame length and its shape, flame situation is easy to control and adjust;

6)Highly adoption to fuel quality;

7)wet process rotary kiln is in the high temp situation, so Rotary kiln nozzle should be durable and high temp resistance, so some measures of high temp resistance to avoid nozzle destroy.

8)Wet process rotary kiln pipeline of transporting coal should be suitable to spraying part.

Working Principle of Cement Rotary Kiln:

Cement is sent to cylinder from higher end by the hooper. Along with cylinder inclination and rotation, Cement moves by peripheral direction and simultaneously makes compound movement from higher end to low end. Cement finally is discharged from cylinder and enters into cooler.

Fuel is injected from head kiln, and then is fueled to produce heat, making cement become clinker. The hot air produced from heat exchange flows from feeding end to the kiln system, and finally discharge from chimney.

Features of Wet Process Cement Rotary Kiln with High Temp kiln:

1)strong adaptation to non-homogeneity raw material.

2)Even raw material element, stable technology, high quality clinker, high-grade clinker strength.

3)Less dust in grinding process and tail-head;

Why us:

The Following Goals is What We Are Pursuing for Our Clients All Our Life:

1>High output and operating security

2>Low noise and low energy consumption

3>Optimize your labor organization

4>Increase accessory's service life

5>Keep the persuit of sustainable development policy

Superiority of Kuangyan Machinery

1>more than 20 Years production experience

2>Various full sets of production line

3>Bring advanced technology from foreign countries.

4>Set of Lab equipment offered to test material result before delivery

Delivery site

Compant profile

Henan Kuangyan Heavy Machinery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35