|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

rotary kiln dryer rotary kiln seal used calcination rotary kiln

| Price: | 60000.0~900000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

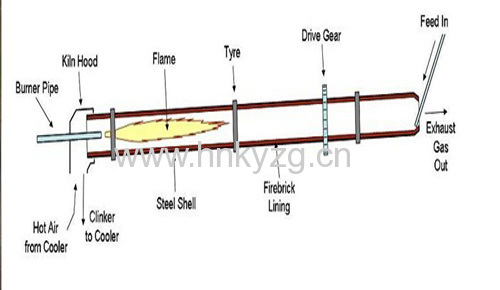

Rotary kiln:

1,Advanced national technologies

2,Efficiency running rate

3,High product

4)ISO CE CV CQC

saving rotary kiln for cement production line and cement plant

Rotary kiln Introduction:

Rotary kiln cement plant is the main equipment of calcining the cement clinker. The characteristics of a rotary kiln are with simple structure, convenient and reliable control of the producing process, with little wearing parts and high running rate. It is the equipment calcining the high grad cement in the cement factory. The rotary kiln is widely used in the metallurgy, chemical industry, construction and other industries.

Rotary kiln Features:

1) The rotary kiln cement plant is an inclined rotary cylinder, the raw material enter the cylinder through the high end of the machine, then move in with the movement of of the rotary kiln. Therefore, the rotary kiln is a conveying equipment.

2) Rotary kiln cement plant is a combustion device.

3) Rotary kiln has the function of heat exchange.

4) Rotary kiln cement plant has the chemical reaction function.

5) The rotary kiln cement plant has the function of degrading and re-using the waste.

Introduction

1.We sell a brand new Cement plant including erection and supervision.

2.We herewith offer according our terms and condition the following entire plant.

3.Many thanks for your enquiry and would submit with pleasure in private order with no binding and exemptible according the Chinese rules.

4.Manufacturer: Jiangsu Pengfei Group; CE, ISO certified

5.Delivery, assembly, erection and putting in operation of a complete cement production

6.Plant with a capacity of 300- 6000 ton clinker per day.

Main equipments like kiln, preheater, mills, roller press, dust collector, crusher, cooler will be produced in factories of Pengfei. Other equipments like electric equipments, motor and gear box will be purchased from Chinese best suppliers, including SIEMENS, FLENDER, SEW Chinese branch.

Design and layout of the plant is for production of Portland cement, Type 42.5R/N.

The dry process is very well known and can be inspected and controlled in many production plants erected by Pengfei.

The complete equipment, devices and accessories can be inspected and controlled on site/location of manufacturer before loading.

Scope of delivery and service:

- Feasibility study (development of cement quantity ratios and analysis of raw materials).

- Creating of basic engineering

- Creating of construction (as-built documentation)

- Delivery of the complete plant equipment

- Delivery of automation system

- Delivery of electrical kits

- Delivery of Lab and test engineering station for permanent quality monitoring

- Erection the entire plant on the prepared foundations.

- Taking in function (set and run up) of the entire plant.

- Training of customer's operating staff

- Hand over operating manuals and trouble shooting guide line

- One year full replacement warranty!

The delivery does not include:

- Delivery and transport from the customer's harbour to the erecting place

- Civil work

- Any building work

- Grounding work

- Entire steel frame work

- Lightning protection

Scope of erection:

- Erecting of the entire plant equipment by an experienced erecting team of Pengfei;

- The erection will be done only in a safe country. In case of erecting in an insecure country like IRAQ or IRAN or Central African State etc. are higher costs considered as agreed!

- Therefore has to be a separate installment plan verified between the parties!

Delivery time: 10 months; 24 months till run up;

Payment: before loading, according the following installment plan:

30% Down payment after signing the sales contract within 10 days

30% FOB Shanghai first ship

30% FOB Shanghai second ship

10% after 1 year production (time of warranty)

Warranty: 1 year full warranty

Reservation of title: until receiving the entire payment. Extended reservation of title is valid.

Further explanation:

1.This cement plant will be designed for continuous production of Portland cement according R/N type of 42.5 (CIM I/II) as well as composite cement according the European regulation EN 197-1.

2.This offer is a very good opportunity to safe almost the 1/3 of the ordinary European pricing of such kind of plant.

3.The supplier will send a team for supervising to the real purchaser for very fair conditions.

Applications of Henan calcination rotary kiln with ISO certification :

1) Rotary kiln is the key equipment in cement industry for calcining clinker.Both dry and wet methods are applicable.

2) It is also used in various industries, such as metallurgy, chemistry, building, refractory material, environmental protection, etc.

3) Lime kiln can bake active line and dolomite, and thus are popular in steel factory and ferroalloy factory.

4) The kiln is composed of the cylindrical shell, roller supporting device with thrust roller, driving gear unit movable kiln hood, sealing device at kiln inlet, coal dust pipe device etc.

Working Principle:

1) With a certain slope to the level, the whole kiln body is supported by rollers and fitted with thrust rollers to control up and down movement of the kiln body.

2) Besides main driving unit for driving system, it is also fitted with the auxiliary driving unit so as to ensure the kiln body still can rotating when the main motor is powered off and prevent it from deforming.

3) The kiln head adopts housing type sealing and kiln rear uses axial contact sealing unit so that reliability of sealing could be ensured.

Main technical parameters

Type | Modal | Barrel diameter (mm) | Barrel length (mm) | Slope (percentage) | Capacity (t/h) | Speed (rpm) | Motor power(kw) | Weight (t) |

Straight tube rotary kiln | YZ1225 | 1200 | 25000 | 4 | 3 | 0.53-5.25 | 22 | 34 |

YZ1632 | 1600 | 32000 | 4 | 3.5 | 0.53-5.25 | 15 | 46.82 | |

YZ1828 | 1800 | 28000 | 4 | 4 | 0.28-2.84 | 30 | 59.39 | |

YZ1845 | 1800 | 45000 | 4 | 4.5 | 0.26-2.61 | 30 | 80 | |

YZ1636 | 1600 | 36000 | 4 | 1.2-1.9 | 0.26-2.61 | 22 | 51.023 | |

YZ1939 | 1900 | 39000 | 4 | 1.6-3.4 | 0.31-2.82 | 37 | 70.704 | |

YZ2044 | 2000 | 44000 | 3.5 | 2.4-4 | 0.22-2.26 | 37 | 97.135 | |

YZ2245 | 2200 | 45000 | 3.5 | 3.2-5.3 | 0.23-2.25 | 45 | 125.462 | |

YZ2550 | 2500 | 5000 | 3.5 | 6.2-7.4 | 0.68-1.45 | 55 | 179.606 | |

YZ2555 | 2500 | 55000 | 3 | 7.3-9.8 | 0.79-2.38 | 55 | 191.203 | |

YZ2820 | 2800 | 20000 | 4 | 15-18 | 0.8-1.45 | 75 | 186.373 | |

YZ3028 | 3000 | 28000 | 4 | 18-23 | 0.8-1.45 | 75 | 180.737 | |

YZ3060 | 3000 | 60000 | 3.5 | 16-20 | 0.49-2.41 | 90 | 272.510 | |

YZ3226 | 3200 | 26000 | 4 | 22-27 | 0.8-1.45 | 90 | 185.107 | |

YZ 3255 | 3200 | 55000 | 3.5 | 17-23 | 0.1-1.52 | 75 | 271.673 | |

YZ3529 | 3500 | 29000 | 4 | 28-40 | 0.16-1.38 | 110 | 238.031 | |

YZ3560 | 3500 | 60000 | 3.5 | 28-40 | 0.65-2.25 | 125 | 347.872 | |

YZ4030 | 4000 | 30000 | 4 | 52-70 | 0.38-3.52 | 160 | 415.103 | |

YZ4060 | 4000 | 60000 | 3.5 | 55-78 | 0.38-3.52 | 315 | 514.223 | |

YZ4262 | 4200 | 62000 | 3.5 | 80-105 | 0.38-3.52 | 315 | 541.615 | |

YZ 4565 | 4500 | 65000 | 3.5 | 110-140 | 0.38-3.52 | 420 | 609.526 | |

YZ4772 | 4700 | 72000 | 3.5 | 150-190 | 0.38-3.52 | 550 | 795.325 | |

Reducing rotary kiln | YB1626 | 1600/1400 | 26000 | 4 | 0.7-1.1 | 0.41-3.85 | 18.5 | 38.621 |

YB1939 | 1900/1600 | 39000 | 4 | 2.2-2.7 | 0.27-2.58 | 22 | 60.841 | |

YB2245 | 2200/2000 | 45000 | 3.5 | 2.5-3.5 | 0.25-2.28 | 30 | 88632 | |

YB2545 | 2500/2200 | 45000 | 3.5 | 4.5-6.2 | 0.25-2.18 | 45 | 102.367 | |

YB2845 | 2800/2500 | 45000 | 3.5 | 7.5-10 | 0.68-1.45 | 55 | 192.622 | |

YB3560 | 3500/3000 | 6000 | 3.5 | 23-32 | 0.65-2.28 | 125 | 310.263 |

Company profile

Henan Kuangyan Heavy Machiery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35