|

Henan Kuangyan Heavy Industry Machinery Co.Ltd

|

kiln rotary professional rotary kiln industrial rotary kiln

| Price: | 60000.0~900000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

Rotary kiln:

1,Advanced national technologies

2,Efficiency running rate

3,High product

4)ISO CE CV CQC

1. We have been this line for more than 30 years.

2. Our technical is mature.

3. We have our own R&D department.

4. We have devoted ourselves in the international trade for more than 3 years, so we have rich experience

5. We have cooperated with many big companies.

rotary kiln's characteristics:

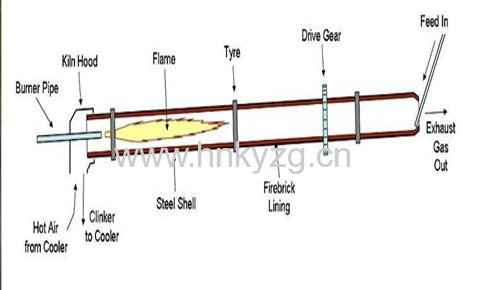

Rotary kiln consisted of support device, catch wheel, gears, the cylinder, sealing equipment and kiln head hood.

Rotary kiln belongs to building material equipment. Rotary kiln according to different processing materials can be divided into cement kiln, metallurgy chemical kiln and lime kiln.

Rotary kiln is a kind of preprocessing device mainly used to sinter cement clinker. Both dry process and wet process are applicable.

As a professional rotary kiln manufacturer in China, we adopt advanced contact type graphite block sealing device and hydraulic catch wheel device to ensure the stable running of kiln.

Our rotary kiln has the features of reliable performance, easy operation, low energy consumption, and high productivity, etc.

Compared to the output and energy consumption of other equipment of the same specification, the output of our rotary kiln has increased by 6-10% and energy consumption has reduced by 16%

Limestone Rotary Kiln Brief Introduction :

1. Limestone Rotary kiln belongs to building material equipment, which can be divided into cement kiln, metallurgy chemical kiln and lime kiln according to different materials. Cement kiln is used for making of cement clinker and there are dry and wet methods to make cement. Metallurgy chemical kiln is used in metallurgy industry and ironworks for lean iron ore, chromium ore and ferronickel ore calcimine.

2. Rotary kiln is used for calcimine of high aluminum vandal ochre in refractory material industry, calcimine of calotte and aluminum hydroxide in aluminum manufacturer, claiming of chrome sand ore and chrome powder ore in chemical plant.

Structure Features of Rotary Kiln:

The kiln shell is made of rolled steel plates; its structure is optimized by computer software, and features" longitudinal flexible and transverse rigid", which improved the loading of supporting device and stability of refractory lining,

The supporting roller bearings features smaller width over diameter ratio L/D, leading to its higher reliability.

The special high-started torque motor for cement industry rotary kiln is applied for driving system.

The sealing of labyrinth plus spring pressing with asbestos heat isolation layers attached, is applied higher so that reliability and longer service life of sealing are achieved.

Application of Rotary Kiln:

1. Rotary kiln is commonly used in the production process of catalytic agent, molecular sieve and zinc oxide, etc. As a result, you can find a rotary kiln in variety of industries, like steel annealing and nonferrous smelting industries, metallurgy and chemistry fields, and building industries, and more.

2. Rotary kiln system, which is also called a rotary calcine kiln, is a commonly used building material machine. Classifying by material properties, a rotary kiln falls into cement kilns, metallurgy chemical kilns, and lime kilns.

Working Principle of Rotary Kiln:

1) With a certain slope to the level, the whole kiln body is supported by rollers and fitted with thrust rollers to control up and down movement of the kiln body.

2) Besides main driving unit for driving system, it is also fitted with the auxiliary driving unit so as to ensure the kiln body still can rotating when the main motor is powered off and prevent it from deforming.

3) The kiln head adopts housing type sealing and kiln rear uses axial contact sealing unit so that reliability of sealing could be ensured.

Main Technical parameters

Type | Modal | Barrel diameter (mm) | Barrel length (mm) | Slope (percentage) | Capacity (t/h) | Speed (rpm) | Motor power(kw) | Weight (t) |

Straight tube rotary kiln | YZ1225 | 1200 | 25000 | 4 | 3 | 0.53-5.25 | 22 | 34 |

YZ1632 | 1600 | 32000 | 4 | 3.5 | 0.53-5.25 | 15 | 46.82 | |

YZ1828 | 1800 | 28000 | 4 | 4 | 0.28-2.84 | 30 | 59.39 | |

YZ1845 | 1800 | 45000 | 4 | 4.5 | 0.26-2.61 | 30 | 80 | |

YZ1636 | 1600 | 36000 | 4 | 1.2-1.9 | 0.26-2.61 | 22 | 51.023 | |

YZ1939 | 1900 | 39000 | 4 | 1.6-3.4 | 0.31-2.82 | 37 | 70.704 | |

YZ2044 | 2000 | 44000 | 3.5 | 2.4-4 | 0.22-2.26 | 37 | 97.135 | |

YZ2245 | 2200 | 45000 | 3.5 | 3.2-5.3 | 0.23-2.25 | 45 | 125.462 | |

YZ2550 | 2500 | 5000 | 3.5 | 6.2-7.4 | 0.68-1.45 | 55 | 179.606 | |

YZ2555 | 2500 | 55000 | 3 | 7.3-9.8 | 0.79-2.38 | 55 | 191.203 | |

YZ2820 | 2800 | 20000 | 4 | 15-18 | 0.8-1.45 | 75 | 186.373 | |

YZ3028 | 3000 | 28000 | 4 | 18-23 | 0.8-1.45 | 75 | 180.737 | |

YZ3060 | 3000 | 60000 | 3.5 | 16-20 | 0.49-2.41 | 90 | 272.510 | |

YZ3226 | 3200 | 26000 | 4 | 22-27 | 0.8-1.45 | 90 | 185.107 | |

YZ 3255 | 3200 | 55000 | 3.5 | 17-23 | 0.1-1.52 | 75 | 271.673 | |

YZ3529 | 3500 | 29000 | 4 | 28-40 | 0.16-1.38 | 110 | 238.031 | |

YZ3560 | 3500 | 60000 | 3.5 | 28-40 | 0.65-2.25 | 125 | 347.872 | |

YZ4030 | 4000 | 30000 | 4 | 52-70 | 0.38-3.52 | 160 | 415.103 | |

YZ4060 | 4000 | 60000 | 3.5 | 55-78 | 0.38-3.52 | 315 | 514.223 | |

YZ4262 | 4200 | 62000 | 3.5 | 80-105 | 0.38-3.52 | 315 | 541.615 | |

YZ 4565 | 4500 | 65000 | 3.5 | 110-140 | 0.38-3.52 | 420 | 609.526 | |

YZ4772 | 4700 | 72000 | 3.5 | 150-190 | 0.38-3.52 | 550 | 795.325 | |

Reducing rotary kiln | YB1626 | 1600/1400 | 26000 | 4 | 0.7-1.1 | 0.41-3.85 | 18.5 | 38.621 |

YB1939 | 1900/1600 | 39000 | 4 | 2.2-2.7 | 0.27-2.58 | 22 | 60.841 | |

YB2245 | 2200/2000 | 45000 | 3.5 | 2.5-3.5 | 0.25-2.28 | 30 | 88632 | |

YB2545 | 2500/2200 | 45000 | 3.5 | 4.5-6.2 | 0.25-2.18 | 45 | 102.367 | |

YB2845 | 2800/2500 | 45000 | 3.5 | 7.5-10 | 0.68-1.45 | 55 | 192.622 | |

YB3560 | 3500/3000 | 6000 | 3.5 | 23-32 | 0.65-2.28 | 125 | 310.263 |

Company profile

HenaN Kuangyan Heavy Industrial Machiery Co., Ltd. is specialized in heavy equipment like various crushers, magnetic separators, mining machines, bricks and blocks machines, cement production line, AAC block line, etc., which is located in the middle of China. Our competitive price, high quality products and excellent after-sales service had gain us good reputation in this field.

Our company is headquartered in Zhengzhou Country's High-tech Industrial Development Zone, which consists of three branches, a research and development department. Since the establishment of the company, always adopt advanced modern management system, and focused on innovation, has brought together a number of scientific and technological elite, the company employees is more than 500people now, with 20 senior engineers, and more than 100 midding technicians. The company has long-term cooperation with domestic scientific research units, has introduced advanced technology, technics and testing system at home and abroad.

Our service:

1. Pre-sales services:

1) Select proper equipment model;

2) Design and manufacture products according to clients' special requirement;

3) Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

2. Services during the sale:

1) Make sure goods prepared within delivery time;

2) Pre-check and accept products ahead of delivery;

3) Prepare documents required to help customer pass customs clearance;

4) Help clients to make Project evaluation and feasibility analysis and draft solving plans.

3. After-sales services:

1) Assist clients to prepare for the first construction scheme;

2) Install, debug and examine the equipment;

3) Train technical personnel the first-line operators;

4) Provide technical exchanging;

5) Offer spare parts at a best price for long term.

Note: Responsible for handling other required matters conforming the state regulations

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35